Shenzhen WOW Packaging Display Co., Ltd. is one of the leading manufacturers and suppliers of 3 tiers cardboard pop counter displays in China, featured by quality products and good price. Be free to buy advanced 3 tiers cardboard pop counter displays made in China here and get pricelist from our factory. Customized orders are welcome.

WOW has its own structure and graphic designer, we help customers to customize the popular display structure design and graphic design for free.

With 9 years of POS display manufacturing and design experience, our designers provide this unique design based on our clients' products, helping to double their sales.

If you don't have an idea, contact us, we offer several suggested options!

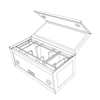

3 Tiers Cardboard POP Counter Displays

Details of pop counter displays are:

| Product Name | 3 Tiers Cardboard POP Counter Displays |

| Material | 350g CCNB+BE Flute |

| Printings | CMYK/Panton Color |

| Surface Treatment | Matt / Glossy / Oil/UV /Embossed/Stamp |

| Available Accessory | Hooks,Turnable Plate,Mirror, |

| Packing Method | Flat packing (1 set/ carton or 5 sets/ carton ),Assembled Packing,Semi-assembled Packing |

| Quality Inspection | 100% inspected or accept 3rd party inspection and loading supervision |

| Shipping Method | China local delivery,Global Sea shipment,Air Express,Train & Truck Shipping |

| Incorterm | EXW,FOB,CIF.DDP.DDU |

| Sample Lead Time | 3 days and sample fee could be refund |

Q: How many orders are made?

A: The general pop counter displays has a minimum order quantity of 100 sets, and the smaller display case has a minimum order quantity of 200 sets.

Q: Why are the thickness of large cardboard and sample cardboard different?

A: The reason why the thickness of the board and the bulk of the cardboard is different is because the machine used is different. The paperboard of the sample is directly smashed on the paperboard by printing, and then cut by a cutting machine, and the thickness of the paper is cut without change; and for large goods, the printed paper is first smashed on the pit paper by a paper machine. (This is the first paper being pressed). Then, take the good cardboard and take it to the beer machine for beer pressing. The pre-made knife mold is placed in the beer machine, and the beer machine presses the knife mold on the paperboard to make the shape of the beer (this is the second paper pressing process), but only the place where the knife mold is pressed will be crushed. The materials and samples used in the bulk cargo are exactly the same.