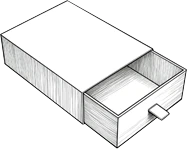

The right paper substrate can make or break a packaging project. Whether you are designing a display box for retail, a heavy‑duty shipping carton, or a luxury gift sleeve, understanding each paper grade's strengths and limitations is the first step toward controlling cost and protecting brand equity.

In the packaging industry, various types of paper may be used. This article will look at seven different types of paper used in the packaging industry:

Kraft Paper (Unbleached & Bleached)

Characteristics: High strength, good toughness, and excellent tear resistance.

Kraft paper, recognised for its long pine fibres and high mechanical strength, is the workhorse of industrial sacks, grocery carriers, and e‑commerce envelopes. Unbleached kraft delivers a rustic, eco‑forward aesthetic, while bleached varieties accept vibrant print for mid‑range display cardboard box applications such as coffee pouches or seed packets. Thanks to a 90 % recycling rate in North America (FBA 2024), kraft remains one of the most sustainable choices for primary and secondary packages.

Solid Bleached Board (SBS)

SBS-sometimes called "white card"-is produced entirely from bleached chemical pulp. Its silky surface and consistent caliper make it ideal for cosmetics sleeves, pharma cartons, and premium display boxes that demand fine graphics, foil, or embossing. Although priced roughly 18 % higher than comparable duplex board, brands recoup the cost by achieving near‑photographic reproduction without a separate label.

Features – smoothness that supports foil, emboss, and high‑gloss varnish.

Uses – High‑end cosmetics, electronics inserts, and gift display boxes.

Coated & Uncoated Wood‑Free Paper (C2S / Offset)

Wood‑free means lignin is removed, preventing yellowing. Coated grades have clay or calcium carbonate for gloss; uncoated remain matte and writable.

These papers bridge the gap between print collateral and light packaging. Double‑coated (C2S) sheets accept rich inks for inserts, wrap‑around labels, or the outer panels of hybrid cardboard packing designs. Uncoated offset stocks, while less glossy, offer excellent writability-perfect for subscription boxes that include personalised notes.

Watch out – Less rigid than board grades; not suited for structural cartons unless laminated.

Duplex Board (Grey‑Back or Kraft‑Back)

Composition – Recycled fibre core with a white, often clay‑coated, printing surface.

Advantages – Up to 25 % cheaper than SBS, yet offers respectable stiffness for large folding cartons.

Duplex board features a white, printable front layer and a grey or kraft reverse made from recycled fibres. It balances strength and economics, making it a top pick for toy cartons, small‑appliance packs, and budget‑sensitive display cardboard boxes. Surface smoothness is sufficient for CMYK + 1 spot colour, but it is less suited to high‑gloss varnishes than SBS.

Corrugated Board (A/B/C/E/F Flute)

Structure – Fluted medium bonded between two liners. Flute height (A > C > B > E > F) determines cushioning and caliper.

Core properties:

- Edge Crush Test (ECT): ≥ 44 lbs for single‑wall C‑flute

- Cushion curve: Up to 65 % shock absorption versus solid board

Corrugated board merges vertical flutes with two flat liners, providing unbeatable stacking strength and cushioning. Variations such as E‑flute or F‑flute allow slim profiles for retail display boxes that still need rigidity-think 24‑pack beverage trays or countertop dump bins. Digital printing on HP PageWide presses now enables full‑colour graphics directly on corrugated, eliminating litho‑lam costs for short‑run promotions.

Honeycomb Board

Make‑up – Hexagonal kraft core sandwiched by liners.

Featuring a kraft honeycomb core sandwiched between liners, this material delivers exceptional strength‑to‑weight ratio. Furniture brands use it for interior dunnage, while automotive suppliers adopt it for Class‑A part crates. For packaging engineers seeking to replace plywood, honeycomb offers a 40 % weight reduction and is fully recyclable alongside corrugated streams.

Specialty Papers (Barrier & Decorative Grades)

Advances in water‑based barrier coatings now let paper rival plastic for grease, oxygen, or moisture protection-crucial in frozen foods and pet treats. Meanwhile, UV‑reactive, pearlescent, or tactile‑embossed sheets elevate luxury display boxes and limited‑edition spirits packs.

Paper Quick Facts

|

|

Paper Grade |

Typical Basis Weight (g/m²) |

Key Characteristics |

Common Packaging Uses |

|

1 |

Kraft Paper |

70–300 |

High tensile strength, rustic look |

Grocery bags, mailers |

|

2 |

Solid Bleached Board (SBS) |

200–400 |

Smooth premium surface, pure white |

Cosmetics sleeves, luxury cartons |

|

3 |

Coated / Uncoated Wood Free |

80–250 |

Excellent print clarity, writable |

Inserts, wrap around labels |

|

4 |

Duplex Board |

250–450 |

White front, grey back, economical |

Toy boxes, appliance cartons |

|

5 |

Corrugated Board |

A/B/C/E/F flute |

Cushioning flutes + liners |

Shipping cartons, POS dump bins |

|

6 |

Honeycomb Board |

300–1000 (panel) |

Lightweight yet strong |

Heavy duty crates, furniture pads |

|

7 |

Specialty Papers |

Variable |

Functional or decorative finishes |

Barrier pouches, gift packs |

How to Choose the Best Grade for Your Display Needs

1. Product Weight & Size

A 1‑kg jar requires at least a B‑flute corrugated holder, whereas lipstick blister cards thrive in 350 g/m² SBS.

2. Printing & Finishing Specs

If you need spot UV, choose a coated surface. Kraft liners mute gloss effects but resonate with eco‑minded demographics.

3. Budget & Volume

Small test runs (< 1,000 units) may lean on digital print duplex to avoid tooling charges; high‑volume (> 20 K) promotions justify die‑cut corrugated and offset litho.

4. Supply‑Chain Complexity

Brands shipping globally should prioritise flat‑packed designs to slash freight. A knock‑down corrugated display cardboard box can reduce cube by up to 70 %.

From rugged corrugated cartons to high‑gloss carton boards, each paper grade brings unique value to the packaging spectrum. Evaluating load requirements, print ambitions, and sustainability targets will guide you to the optimal choice-whether it's a mass‑market display cardboard box or a bespoke luxury sleeve. As material science evolves, expect even lighter, stronger, and more eco‑friendly options to emerge, empowering brands to meet both commercial and environmental KPIs.