What Is Honeycomb Cardboard?

Honeycomb cardboard is a structural paper-based material engineered with a hexagonal core sandwiched between flat linerboards. This internal structure mimics the geometry of a natural honeycomb, allowing the material to achieve high strength while remaining lightweight. In the display and packaging industry, it is commonly referred to as honeycomb corrugated cardboard or honeycomb corrugated board.

Unlike traditional corrugated cardboard that relies on linear flutes, corrugated cardboard honeycomb distributes pressure evenly across its surface. This makes honeycomb cardboard sheets especially suitable for applications that require rigidity, load-bearing performance, and dimensional stability without adding unnecessary weight.

Because of these properties, honeycomb corrugated materials are widely used in exhibition displays, retail fixtures, industrial packaging, furniture components, and large-format visual installations.

Advantages of Honeycomb Cardboard Display

A Honeycomb Display offers a balanced combination of performance, sustainability, and design flexibility. These advantages are not theoretical-they are measurable and widely recognized across exhibition and retail industries.

High Strength with Low Weight

Honeycomb corrugated sheets can achieve excellent compressive strength due to their internal cell structure. Depending on core thickness and paper density, honeycomb corrugated board can support loads several times heavier than standard corrugated board of the same weight.

Material Efficiency

Because the honeycomb core uses less paper to achieve structural rigidity, honeycomb cardboard displays reduce raw material consumption while maintaining performance. This efficiency is particularly valuable for large-scale exhibition builds.

Flat, Print-Ready Surfaces

The outer liners of honeycomb cardboard sheets are smooth and stable, making them ideal for direct printing, lamination, or vinyl application. This allows brands to achieve high-quality graphics without additional mounting substrates.

Sustainability and Recyclability

Most honeycomb cardboard packaging and display solutions are made from recyclable kraft paper. At the end of their lifecycle, panels can be processed through standard paper recycling systems, aligning with corporate sustainability goals.

Logistics and Handling Benefits

Lightweight construction lowers shipping costs and simplifies on-site handling. For international exhibitions or multi-location rollouts, this can significantly reduce overall project expenses.

Why Choose Honeycomb Cardboard Exhibition Stands?

A honeycomb display stand is particularly well suited for exhibitions, trade shows, pop-up events, and temporary brand installations. These environments demand materials that are strong, visually clean, and easy to manage within tight setup schedules.

Traditional exhibition systems often rely on aluminum frames, PVC boards, or composite panels. While durable, these materials increase shipping weight and often require tools or skilled labor for assembly. In contrast, honeycomb corrugated cardboard enables faster installation with fewer components.

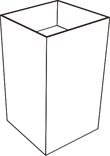

From a structural standpoint, honeycomb corrugated board panels can achieve compressive strength levels suitable for full-height walls, freestanding towers, and self-supporting display elements. When properly engineered, honeycomb display stands can perform reliably throughout multi-day events without deformation.

From a brand perspective, honeycomb cardboard displays provide uninterrupted graphic surfaces, helping brands maintain a clean and professional visual identity on the show floor.

Design Flexibility and Superior Applications Over Traditional Materials

One of the strongest advantages of honeycomb corrugated cardboard is its adaptability. Unlike rigid materials such as PVC foam board or solid plastic panels, honeycomb corrugated board can be processed into a wide range of structural forms without compromising integrity.

This makes it highly effective for:

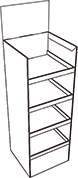

Freestanding Structures

Honeycomb display stands maintain stability even at larger sizes, making them suitable for exhibition back walls, product towers, and branded partitions.

Suspended Installations

The lightweight nature of honeycomb corrugated sheets allows for ceiling-mounted signage and overhead elements with reduced load requirements.

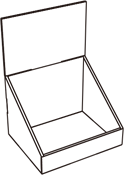

Three-Dimensional Product Displays

Multi-layer constructions using honeycomb cardboard sheets create depth and structure, helping products stand out in crowded exhibition environments.

Curved or Geometric Designs

Unlike rigid boards that remain flat, honeycomb corrugated board can be segmented or engineered into curved or angular shapes, adding visual movement and architectural interest.

Compared with traditional materials, honeycomb cardboard offers greater creative freedom while maintaining structural reliability.

Innovative Applications of Honeycomb Display in Exhibitions

Modern exhibitions increasingly prioritize modularity, sustainability, and efficient reuse. Honeycomb Display systems align well with these priorities.

Common exhibition applications include:

- Modular booth walls and frames

- Temporary retail installations

- Brand experience zones

- Product launch stages

- Event backdrops and visual panels

Because honeycomb cardboard packaging and display components can be digitally cut and modularized, many exhibitors reuse structural elements across multiple events, replacing only printed surfaces. This approach reduces waste, lowers long-term costs, and shortens production timelines.

In addition, honeycomb corrugated cardboard can be treated to meet fire-retardant standards required by many international exhibition venues, further expanding its usability.

FAQs About Honeycomb Corrugated Cardboard

1. Is a honeycomb display stand strong enough for large exhibitions?

Yes. When designed with the appropriate thickness and core density, a honeycomb display stand can support large panels, vertical walls, and freestanding structures commonly used in exhibitions.

2. How does honeycomb corrugated cardboard differ from standard corrugated board?

Honeycomb corrugated cardboard uses a hexagonal core structure that distributes load more evenly than traditional fluted corrugation, resulting in higher stiffness with less material.

3. Are honeycomb cardboard sheets reusable?

In many cases, yes. Honeycomb cardboard sheets can be reused multiple times if they are properly handled, stored, and designed within modular systems.

4. Is honeycomb cardboard packaging environmentally sustainable?

Honeycomb cardboard packaging is typically made from recyclable paper materials and supports waste reduction through material efficiency and recyclability.

5. What thickness options are available for honeycomb corrugated board?

Honeycomb corrugated board is available in various thicknesses, commonly ranging from 10 mm to over 50 mm. Selection depends on load requirements, display size, and structural design.