Retail shelves don't wait. Products move in and out constantly, promotions change weekly, and store staff are expected to replenish shelves fast, often with limited manpower. In this environment, packaging is no longer just about protection during transport. It directly affects how quickly a product reaches the shelf and how it is presented to shoppers.

This is where retail ready packaging becomes a practical requirement rather than a design trend.

Retail ready packaging, sometimes called ready retail packaging or shelf ready packaging, is designed to move products from warehouse to shelf with minimal handling. Instead of opening cartons, removing inner packs, and manually facing products, store staff can place the packaging directly onto the shelf after a simple opening step.

For brands, this type of ready packaging is about control. It ensures that products appear on the shelf exactly as intended, regardless of store location, staff experience, or replenishment speed.

What Is Retail Ready Packaging?

Retail ready packaging (or shelf ready packaging) refers to a box, tray, sleeve, bin, or other display that product is shipped in that can be set on the shelf upon arrival at a store. This product does not have to be removed from its container to be placed on the shelf. The container it is shipped in serves as a display unit for the merchandise.

The key characteristics of retail ready packaging are:

- Clear identification of brand and product information (variety, count, size, etc.)

- Openings that can tear-away for a smooth edge and don't require extra cutting/slicing

- Eliminates the need to unpack individual items

- Easy to replenish - built for stocking cases on shelves two-deep

- Designed for a quick, "one touch" movement onto shelves

- Effortless to disassemble and dispose of after use

A well-designed ready shelf packaging solution protects products during shipping, opens cleanly in-store, and then becomes part of the shelf layout. There is no repacking stage in between.

Most shelf ready packaging boxes include structural features such as tear-away panels, perforated fronts, reinforced bases, or built-in display lips. These elements allow the packaging to convert quickly from a closed carton into an open-facing display.

This approach reduces unnecessary handling. Fewer touchpoints mean faster replenishment, fewer mistakes, and less product damage - all critical factors for high-volume retail operations.

RRP Packaging Requirements

Although each retailer has its own documentation, most retail ready packaging requirements are built around real in-store workflows rather than design preferences.

Clear Product Identification

Outer packaging must clearly communicate what is inside. This includes product name, SKU, barcode, orientation, and unit count. Store staff should be able to identify the product without opening the box.

In large retail chains, unclear labeling slows down replenishment and increases the risk of misplacement.

Fast and Tool-Free Opening

One of the most important requirements of ready packaging is ease of opening. Retailers expect packaging to open within seconds, without knives or cutters. Poor perforation design can lead to torn displays, damaged products, or safety issues.

Shelf Compatibility

Shelf ready boxes are designed to match standard shelf depths and heights. Packaging that is too deep, too tall, or unstable after opening creates problems on the shelf and is often rejected.

Minimal Waste Handling

After opening, excess cardboard should be easy to remove and recycle. Retailers strongly prefer shelf ready packaging boxes that reduce backroom waste and cleanup time.

Visual Order on Shelf

Retailers value consistency. A good ready shelf packaging design keeps products aligned, visible, and easy to face forward, even as units are removed during the day.

Types of Shelf-Ready Packaging

Different products require different shelf ready packaging structures. The choice depends on product size, weight, turnover speed, and shelf location.

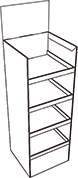

Shelf Ready Trays

Shelf ready trays are one of the most widely used formats. Products sit in an open or tear-front tray that can be placed directly onto the shelf. This format works especially well for fast-moving goods and allows staff to replenish shelves quickly without rearranging items.

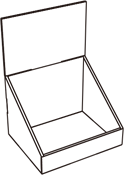

Tear-Away Display Boxes

These are closed cartons with perforated sections. Once the tear panel is removed, the box becomes an open display. This type of shelf ready packaging box balances strong protection during shipping with clean presentation at the shelf.

Gravity-Fed Shelf Boxes

Designed for smaller items, these boxes allow products to slide forward automatically as units are removed. They help maintain a full-facing shelf appearance and reduce manual shelf maintenance.

Modular Shelf Ready Boxes

Some ready packaging solutions are designed to be stacked or combined. This allows retailers to create uniform shelf blocks or promotional displays without additional fixtures.

Benefits of Retail Ready Packaging

The advantages of retail ready packaging go beyond aesthetics. They directly impact operational efficiency and sales performance.

Faster Replenishment

By reducing unpacking steps, ready retail packaging allows store staff to restock shelves quickly, even during peak hours. This helps prevent out-of-stock situations.

Reduced Labor Dependency

Retail labor costs continue to rise. Packaging that simplifies shelf replenishment lowers labor requirements and improves store productivity.

Improved Shelf Consistency

With shelf ready packaging boxes, products maintain a consistent appearance across stores. This is especially important for brands operating in multiple regions.

Lower Damage Rates

Products remain secured until they reach the shelf. Fewer handling steps reduce the risk of crushed corners, broken seals, or missing units.

Better Shopper Experience

Organized shelves, clear product visibility, and easy access all contribute to better shopper engagement. Well-designed ready packaging supports impulse buying and repeat purchases.

RRP at Walmart

Walmart has been a major driver behind the global adoption of retail ready packaging. Its guidelines focus on speed, consistency, and shelf efficiency.

For Walmart suppliers, shelf ready packaging typically needs to:

- Fit standard shelf dimensions

- Open cleanly without tools

- Maintain stability after opening

- Support barcode scanning and inventory systems

Shelf ready trays and tear-away display boxes are commonly accepted formats because they support Walmart's high-volume, fast-turn retail model.

For brands, meeting Walmart's RRP expectations is not just about compliance. Well-executed ready shelf packaging often leads to better shelf presence and improved sell-through.

Frequently Asked Questions (FAQ)

1. Is retail ready packaging only for large retailers?

No. While large chains popularized it, many mid-sized and specialty retailers also prefer retail ready packaging for efficiency and consistency.

2. Does shelf ready packaging limit product branding?

Not necessarily. Shelf ready packaging boxes can still include branded colors, logos, and messaging, as long as they follow retailer guidelines.

3. How do I know which shelf ready format fits my product?

The choice depends on product weight, unit count, shelf size, and turnover speed. Trays, tear-away boxes, and modular designs each serve different needs.

4. Is retail ready packaging more expensive?

Initial packaging costs may be slightly higher, but overall supply chain costs often decrease due to lower labor, fewer damages, and better shelf efficiency.

5. Are shelf ready boxes environmentally sustainable?

Most ready packaging solutions use corrugated cardboard and are fully recyclable. Many designs also reduce excess materials compared to traditional packaging.